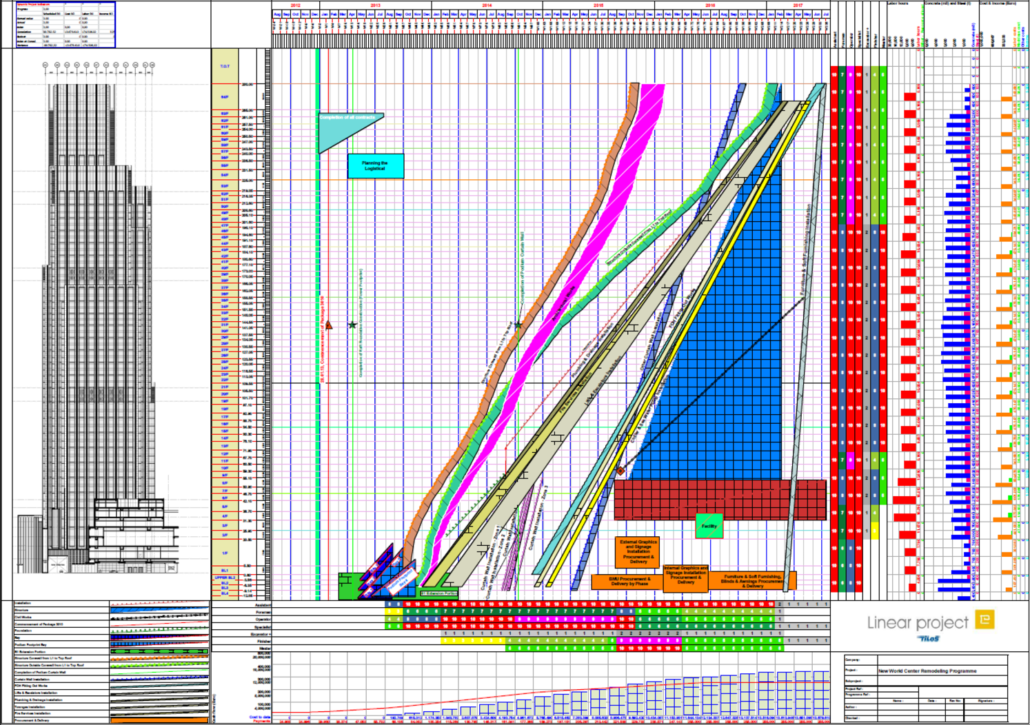

The CPM Schedule vs Linear Scheduling Method

Project Management Systems such as Primavera or MS Project are often used to create a Critical Path Method or CPM schedule for a linear project.

The planner creates a series of discrete activities and then logically connects these activities. Resources can be added to each schedule activity and resource loading can be easily displayed. In order to maintain crew sequencing in a linear-type project, the planner ensures that each activity is connected to its successor by a Start-Start and a Finish-Finish relationship.

These project management tools also produce a GANTT chart. This GANTT chart will then display a graphical representation of the project sequence, and the plan will progress from this baseline.

CPM Schedules may produce an inaccurate baseline

Project management tools such as Primavera or MS. Project automatically plan the project based on the CPM schedule and can be updated more easily than manually updating a GANTT Chart or CAD Drawing. However, they still present issues that threaten the timely completion of a complex linear infrastructure project.

Most estimates and CPM schedules assume a consistent productivity (or work) rate for each crew along the ROW. This productivity factor is then applied for the entire length of the ROW to determine the duration of each crew.

However applying a consistent productivity rate to a crew doesn’t account for changes in profile, terrain, amount of mass haulage required based on ROW elevation, weather changes and many other factors that impact the productivity rate of a crew.

Because of the high likelihood of an inaccurate productivity rate CPM schedules, they simply do not completely or accurately convey the baseline project schedule.

ROW challenges using CPM Schedules are difficult to represent

In cases where the right of way (ROW) access may be interrupted during particular times due to weather, crossings, permitting or other factors external to simple resource allocation, the CPM Schedule as a project management methodology lacks a simple way to easily modify the plan.

Equipment move-arounds then become difficult and clashes become harder to prevent, and almost impossible to proactively manage before construction starts.

Where are we with this project?

For project planning managers, the ability to accurately answer this question and plan for the next section is critical.

And while the typical CPM schedule progress report may show that a crew is 45% complete, it assumes the progress is from start to finish and does not connect completion with the physical ROW. A CPM Schedule does not show exactly where the work has been done and where it is yet to be done.

This approach often causes problems for construction managers.

Linear projects by nature, don’t often progress in a sequential fashion. Equipment move-arounds are standard procedure and it’s necessary to ensure crews are adequately spaced apart.

Planning meetings are still confusing:

While the CPM Schedule sounds like a good project management method for scheduling linear projects, in reality the CPM Schedule only tells half the story of a linear project.

Developed in 1957 specifically for projects that are broken down into a complex series of chronologically discrete activities that are logically connected in a sequence from project start to finish, the Critical Path Method is better suited for the construction of buildings and other facilities (power generating stations, refineries, etc.) and are not adequate for the constructability issues and demands of building linear project such as a pipeline, rail system or roadway.

Conclusion:

As a project management method for complex linear infrastructure projects, using the Critical Path Method to produce GANTT charts is highly ineffective and a drain on resources while failing to produce complete or up-to date information that can be understood by all parties involved.

Simplistic

Simplistic